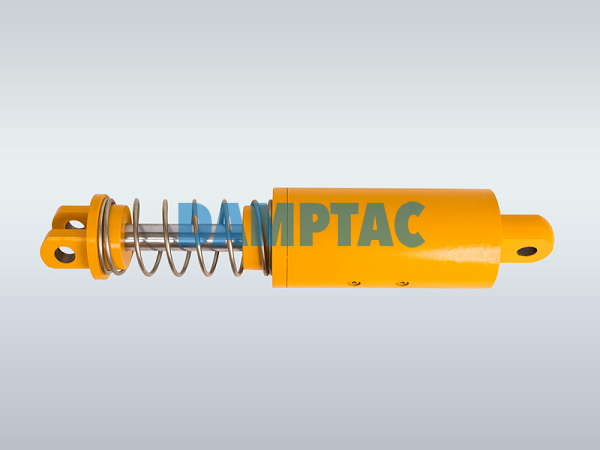

SELF-COMPENSATING HIGH PERFORMANCE BUFFER

The DHB series is a large high performance buffer. According to the application parameters and requirements of each customer, the DHB model designs and manufactures multi-stage precision orifices to meet customer requirements and high-efficiency damping, and provide customers with the best possible damping and damping effect. Compared with high performance LPG DTH series, DHB adopts softer mechanical spring return, which effectively reduces the impact force of tip return. Of course, due to the limitations of mechanical springs, the stroke of the DHB series should not be too long. The DHB model is also suitable for production lines and mechanical equipment that require installation control and repeated operation control. The DampTac DHB series hydraulic high performance buffer meets global occupational safety standards such as OSHA, AISE, CMMA, DIN and FEM.

SPECIFICATIONS

Product Type: Custom Buffer (Each buffer is designed according to customer's actual application parameters)

Product filling: hydraulic oil

Temperature range: standard model (-10 ℃ ~ + 80 ℃), special model (-40 ℃ ~ + 120 ℃)

Reset method: steel spring

Piston rod surface: hard chrome plating

Cylinder body and flange surface: epoxy protective paint (suitable for outdoor use)

Note

Installation requirements:

1. The buffer stroke is within 300 mm, and the angle of side force must be adjusted within 2 °.

2. The buffer stroke is over 300mm, and the side force angle must be adjusted within 1 °.

Maintenance:

If the DHB buffer is used in emergencies and frequent shocks, it is recommended to check it regularly every 3 months. The inspection items are as follows

1. Check the piston rod for scratches, remove dust and corrosive substances on the surface of the piston rod, and spray engine oil.

2. Check for oil leaking around the buffer, especially around the sealing ring.

3. Check whether the piston rod can be fully reset.

4. Since DHB is usually used in severe situations, the bolts and flanges of the fixed buffer can be loosened. Check this

Whether the mounting bolts and nuts of the buffer are loose.

Playground equipment

Rail

Port machinery

Crane

Steel production

Paper machines

Drop hammer etc.

简体中文

简体中文